Quick Information

- Brand Name:Saigao

- Place of Origin:China

- :

Description

Pump Unit

A beam and crank assembly creates reciprocating motion in a sucker-rod string that connects to the downhole pump assembly. The pump contains a plunger and valve assembly to convert the reciprocating motion to vertical fluid movement.

As the beam pumping system rocks back and forth, this operates the rod string, sucker rod and sucker rod pump, which works similarly to pistons inside a cylinder. The sucker rod pump lifts the oil from the reservoir through the well to the surface.

A beam pump is an artificial-lift pumping system which uses a type of reciprocating pump to extract oil from an inland well. Nodding donkeys or beam pumps are a common artificial lift system used in land-based operations.

A pumpjack is the overground drive for a reciprocating piston pump in an oil well. It is used to mechanically lift liquid out of the well if not enough bottom hole pressure exists for the liquid to flow all the way to the surface. The arrangement is commonly used for onshore wells producing little oil.

Because of their characteristic shape and motion, pumpjacks, also called beam pumps, are often given fanciful names such as "lonely birds" and "nodding donkeys." Whatever name you call them, such pumps are critical to crude oil production.

Sucker Rod Pump

sucker rod is a steel rod, typically between 25 and 30 feet (7 to 9 meters) in length, and threaded at both ends, used in the oil industry to join together the surface and downhole components of a reciprocating piston pump installed in an oil well. The pumpjack is the visible above-ground drive for the well pump, and is connected to the downhole pump at the bottom of the well by a series of interconnected sucker rods. Sucker rods are also commonly available made of fiberglass in 37 1/2 foot lengths and diameters of 3/4, 7/8, 1, and 1 1/4 inch. These are terminated in metallic threaded ends, female at one end and male at the other.

The surface unit transfers energy for pumping the well from the prime-mover to the sucker rod string. In doing this, it must change the rotary motion of the prime-mover to reciprocating motion for the sucker rod. And it must reduce the speed of the prime-mover to a suitable pumping speed. Speed reduction is accomplished by using a gear reducer, and rotary motion of the crank shaft is converted to oscillatory motion by means of a walking beam. The crank arm is connected to the walking beam by means of a pitman arm. The walking beam is supported by a Samson post and saddle bearing. The horse head and bridle are used to ensure that the pull on the sucker rod string is vertical all times so that no bearing movement is applied to that part of sucker rod string above stuffing box. The polished rod and stuffing box combination is used to maintain a good liquid seal at the surface.

Sucker Rod pump Pumps

The suck rod pumps can be sunk into wells in sequence as follows: barrel is run down to the setting depth on the tubing and then plunger with the standing valve on the rod string. For tubing of same diameter, tubing pumps are always of larger capacity than insert pumps. The tubing pump is simple in structure and applicable for wells not too deep and of higher production rate.

Tubing pumps are classified as THD pumps and THC or THM pumps. The standing valve of THC or THM pump can be hold and sealed by a mechanical or cup hold-down. Plunger together with standing valve can be lifted out integrally for normal pump check, with the tubing remain intact. This makes the tubing pumps suitable for wells usually with short pump check intervals.

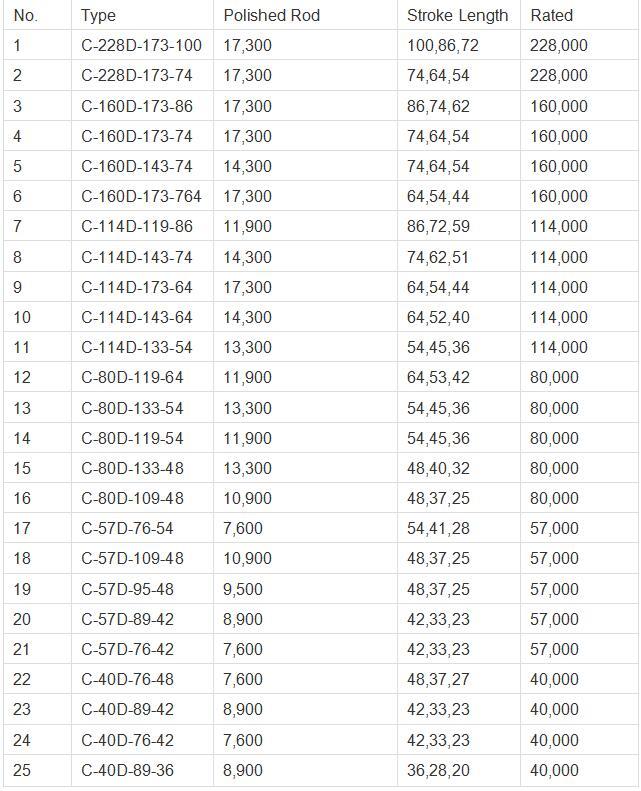

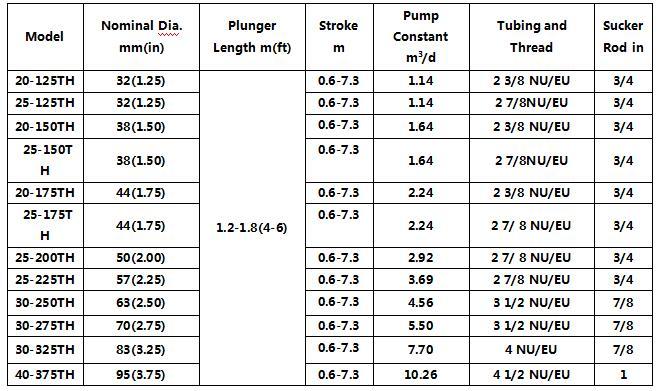

Specifications for Tubing Pumps

Insert Pumps

The insert pump can be connected to sucker rod on the surface and then lowered into the wells integrally through the tubing. Pump checks are easy and without the need of pulling and running the tubing. This makes it especially suitable for deep well applications. Reduced running time and make-and-breaks can surely enhance tubing working life. Insert pumps are clarified as mechanical and cup hold-down pumps by hold-down types or as top hold-down, bottom hold-down and traveling barrel insert pumps by hold-down positions.

Specifications for Insert Pumps

Specialty Sucker Rod Pumps

Specialty sucker rod pumps are applicable for sand, live or high viscous wells, slant wells, or for use in zonal production or casingless production. They have been used in many oilfields with good efficiency.

Various types of specialty pumps and accessories as follows can be designed and made for actual applications and upon client’s request:

1.Plungers electroplated in deep well and then forcefully honed on machines, with electroplated length up to 9m for plungers and longer than 10m for rods and barrel items;

2.Optional stainless-steel plungers, electroplated plungers or Ni-P coated plungers by spray welding processes;

3.High precision valve balls and seats in various materials such as stainless steel, ceramic and carbide.

Packaging & Delivery

- Packing :customed

- Delivery Lead Time :7-15days

- Supply Ability :1000pcs/month